September 30, 2013

New Use: Use Halar on high performance plastics. Halar coatings can be applied to PEEK and other plastics now being used for medical devices, bearings, ultra-high vacuum applications and more.

Why experience counts: When applying Halar to plastic, there’s no electrostatic attraction. Experienced coaters can make additions to the surface of the plastic to create the necessary attraction.

New Use: Use Halar when machinability is an issue. Halar can take heavy machining on exact contact points to get precise thicknesses where they’re needed. We’ve found the machinability of Halar especially useful for plating racks.

Why experience counts: Halar can be built up from 5mls to 80 mls, but this can be tricky. Halar application experts know how to build up thickness without dripping or burning the coating (curing Halar can be more of an art than a science, with curing temperatures constantly in flux). And here, again, after 5 mls, the electrostatic attraction becomes an issue, so understanding how to create the proper thermal attraction is important.

Common Uses for Halar® ECTFE Coatings

-

Chemical industry: Halar offers excellent chemical resistance (pH 1-14) and barrier properties 10 to 100 times better than those of PTFE or FEP to oxygen, carbon dioxide, chlorine gas, or hydrochloric acid.

-

Semiconductor industry: Halar is a highly pure material and is suitable for use in UPW and chemical applications.

-

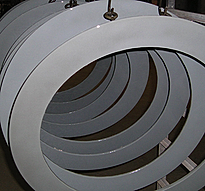

Plating Racks: Halar offers corrosion resistance over a wide temperature range and an extremely smooth surface, free of pinholes.

Doing the coating right the first time with Halar is critical. Because of its excellent adhesion, Halar is not easy to remove, and special equipment is required.

If you’re interested in learning more about Halar® ECTFE, call AIC or check out this excellent Halar® ECTFE properties summary sheet, written by Solvay Solexis.